Noritake’s Vitrified CBN wheels were developed for commercial use in 1971.

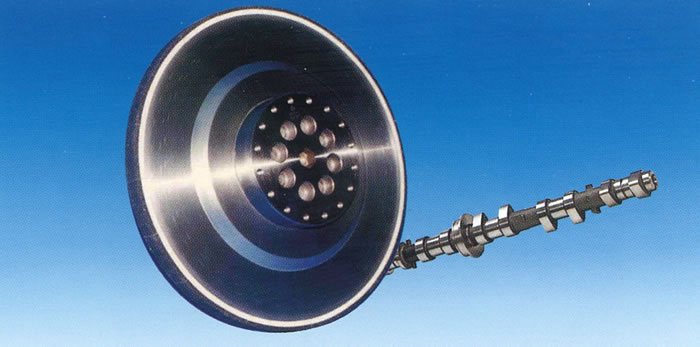

Cubic Boron Nitride grains are the second hardest material in the world. CBN has an outstanding resistance to heat and its sharp structure provides remarkable cutting ability. Noritake CBN wheels were developed for difficult to process metals such as special steels and alloys with problematic configurations.

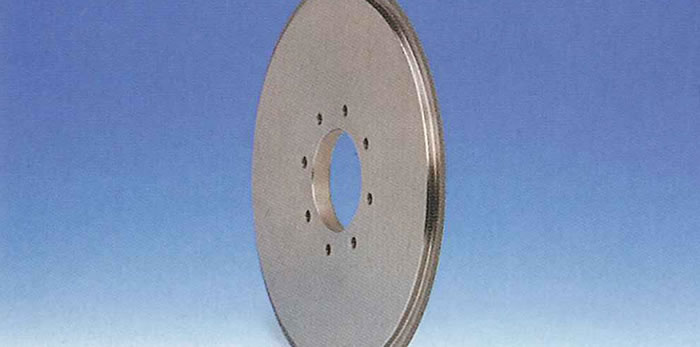

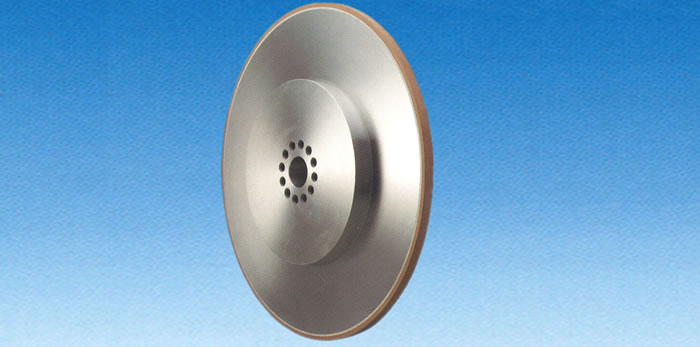

Noritake’s patient structure design CBN wheels are manufactured with high efficiency, high precision and long life. CBN tooling are technologically advanced to be used in a wide range of fields such as the Aerospace, Automobile, and Bearing industries.

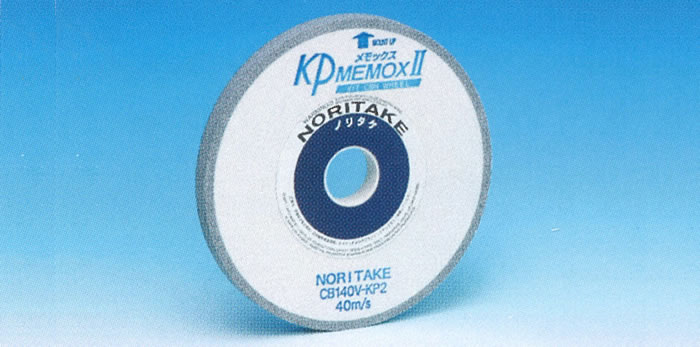

-

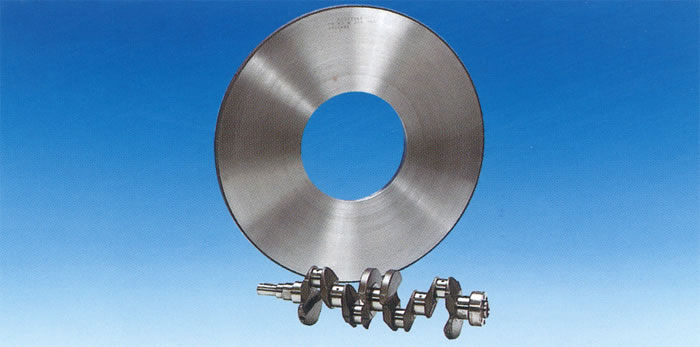

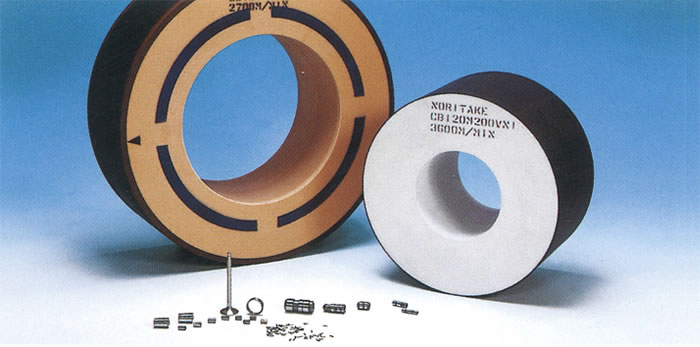

Centerless

The Noritake Centerless grinding wheels are used to manufacture a wide range of parts including Engine Valves, Injection Nozzles, Balance...